6 Forage Establishment Mistakes To Avoid

It’s springtime and we are anxious to get on the land and get our new forage seedings in the ground. There are a few common mistakes made that limit the success of new forage seedings and future yields and quality.

1. Poor Packing

This is a big, but all too common mistake. Forage seed is very small, making good seed-to-soil contact essential for germination, particularly in dry soil conditions. A loose, lumpy seedbed dries out quickly, and lumps make the uniform emergence of young seedlings difficult. A firm, level, clod-free seedbed is very important for uniform seeding depth and good seed-to-soil contact. Avoid creating a soft, fluffy seedbed by deep tillage. Using a spike-tooth harrow before the drill loosens the soil rather than packing it. Soil should be firm enough at planting for a footprint to sink no deeper than 9 mm (3⁄8 inch). If necessary, pack before seeding, in addition to packing after the drill. Packing after seeding results in more rapid and even germination. Use press wheels or pull a packer behind the drill. Sprocket packers are preferable over smooth rollers to reduce the risk of crusting and to push any seed on the surface into the soil.

Figure 1 – Improved germination in tire marks indicates insufficient packing.

2. Using Cheap Seed

Buying cheap forage seed is a poor way to save money. Significant performance differences exist between varieties. The cost of seed is only a very small percentage (typically < 4%) of the cost of producing forage. As land costs increase, the seed cost percentage decreases. The use of the best research proven forage varieties provides high yields of more persistent stands with better disease resistance and appropriate maturity. Using cheap seed has the potential to result in significant yield losses with more risk of disease and winterkill over the life of the stand. It takes very little extra yield to justify higher valued seed.

Certified seed sold under a variety name must meet specific requirements for germination and weed seed content. Forage seed may also be sold as “common seed”. Germination and weed seed content requirements are less rigorous than for certified seed. Common seed has no assurance of characteristics such as disease resistance or winter hardiness. The performance of stands established using common seed is unpredictable and will vary from year to year. The use of high performance, proven varieties, rather than unknown brands or common seed, is strongly suggested.

3. Neglecting Soil Fertility

Forage crops remove a lot of phosphorus (P) (12-14 lbs/tonne P2O5) and potassium (K) (50-55 lbs/tonne K2O) and have high soil nutrient requirements. Alfalfa yields decline rapidly as soil tests drop below 12 ppm P (sodium bicarb) and 120 ppm K. We are seeing more and more soil tests that are critically low in these nutrients, particularly K. Suggested P and K application rates for new seedings are provided in OMAFRA Publication 811, Agronomy Guide, Table 3–6, Phosphate Recommendations for Forages, and Table 3–7, Potash Requirements for Forages. (www.omafra.gov.on.ca/english/crops/pub811/pub811ch3.pdf)

Over the years, with our newer drills we have somehow lost our ability or our willingness to band starter fertilizer in new forage seedings. Starter fertilizer can be especially advantageous in stands where P fertility levels are low to medium. Ideally, MAP starter should be placed 2.5 cm (1 inch) below the seed. Additional fertilizer required can be broadcast and incorporated before seeding.

If sulphur is required, sulphate can be applied at establishment or elemental sulphur applied the previous year. (Sulphur On Alfalfa https://www.qualityseeds.ca/post/sulphur-on-alfalfa )

Figure 2 – Proper forage fertility (right) will improve establishment and subsequent plant health, yield and persistence.

4. Poor Weed Control

Lack of weed control during the establishment period will impact yield and forage quality for the life of the stand. Consistent rotational weed control in other crops before new forage seedings should be done. Perennial weeds should be eliminated before seeding. Herbicide control of broadleaf annual weeds at establishment is especially important in direct seedings.

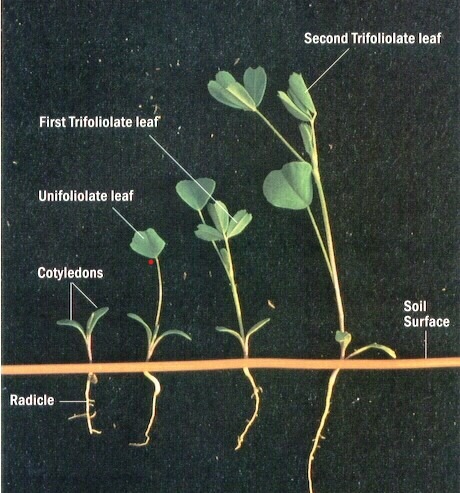

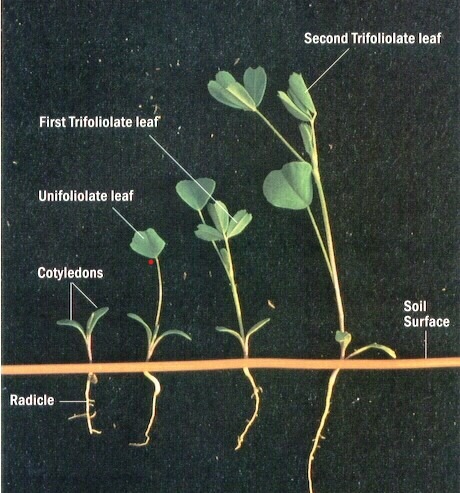

Determine the optimum time of spraying by the stage of development of the new seedlings. The risk of injury to alfalfa seedlings is greatly increased when 2,4-DB application is made outside of the first- to the third-trifoliate stage. 2,4-DB can suppress legume growth for a period of 2 – 3 weeks and severe injury can occur under drought or high temperatures. Uniform emergence as a result of good seedbed preparation and packing make it easier to properly time the herbicide application with reduced risk of legume injury. Target the first-trifoliate stage, where weeds are smaller and easier to control. Grower experience suggests that injury to seedling alfalfa plants can be minimized when reducing the lowest labelled rate of 2,4-DB by 25%. A reduced rate may reduce the level of weed control. (OMAFRA Publication 75, Guide To Weed Control. www.omafra.gov.on.ca/english/crops/pub75/pub75A/pub75Ach8.pdf)

Figure 2 – The risk of injury to alfalfa seedlings is greatly increased when 2,4-DB application is made outside of the first- to the third-trifoliate stage.

5. Harvesting A Cereal Companion Crop As Grain & Straw

Harvesting a companion cereal crop by combining it as grain is not a preferred practice because it often reduces the establishment of the forage crop for the life of the stand. While it is understandable that this is sometimes done to supply much needed straw, it results in considerable risk, especially when the seasons are excessively wet or dry. Allowing cereals to mature to combining extends the period of competition for sunlight and moisture with the new forage underseeding and allows weeds to go to seed. Cereal lodging can injure forage seedlings. Also, if straw lies in the swath for an extended period before baling it has the potential to damage the new forage seeding.

Harvesting the cereal crop at the boot-stage as haylage or baleage reduces the competition, enabling better forage establishment while still allowing weed suppression and erosion control, and providing additional early-season forage. The companion crop is removed before it lodges or competes excessively for light and moisture. Seeding at reduced rates (60 lbs/acre or less) and avoiding N application improves the forage establishment.

6. Not Seeding New Forage Stands Often Enough

Many alfalfa-based stands are simply too old, resulting in huge losses of forage yield. Alfalfa yields are usually at their maximum during the first year or two following the establishment year and then decrease. By the third year, yields have often declined by about 15 – 20%, and possibly 35% by the fourth year. That is a lot of yield to give up! There are many benefits from alfalfa in a rotation in addition to the improved soil health and environment, including:

- 100 lb/ac (110 kg/ha) nitrogen credit to the corn crop following alfalfa in the rotation, and

- 10 – 15% corn yield increase following alfalfa rather than corn after corn.

The nitrogen credit is currently worth about $60. Even with $4 corn, the increased corn yield is close to $100. Adding these two corn crop benefits together, $160 goes a long way in paying the cost of forage establishment somewhere else in the rotation.

Forage stand rotation decisions should be based on forage yield potential, not on the cost of re-establishment. Establishment costs are typically less than 8% of the total cost-of-production (COP) of hay, with the seed costs often less than 4%. Land and harvest costs per acre change little as yields decline, so those costs increase dramatically on a “per lb of yield” basis. Depending on where you farm in the province, the opportunity cost of land rental can represent over 40% of the COP. With high land and harvesting costs, lower yields cost much more than forage establishment costs. When in doubt, rotate!